Oscillation Cutting by Tsugami/Rem Sales

January 29, 2019

What is Oscillation Cutting?

Request more information by clicking here.

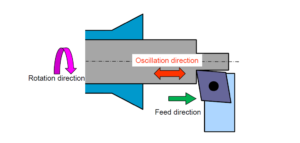

- Oscillation Cutting is a technological breakthrough that oscillates a servo axis to help break chips in tough to cut materials, reduces heat in the cut, while not diminishing tool life.

- This function oscillates the specified axis, and cutting is performed by synchronizing the oscillation of the specified axis with the rotation of the main spindle.

- Interruption in the cut breaks material into small chips.

- This function can be used for turning, drilling, boring, grooving, or cutoff operations.

Benefits of Oscillation Cutting:

- Productivity is increased by significantly reducing operator interruption to remove hanging or bird nesting chips

- Creates the ultimate solution for materials that are normally difficult to break chips

- Capable on multiple axes (currently X1 and Z1)

- Easy to program by special G code

- Oscillation parameters can be changed easily within the program for machining multiple features with multiple tools.

- Can be used for many machining operations including OD turning, drilling, boring, grooving, cutoff

Chips are broken into small pieces and effectively escape the cutting area.

Chips do not break and interfere with workpiece and cutting operations.

Request more information.