SLASH BONE SCREW CYCLE TIMES WITH THE TSUGAMI S206-II!

August 5, 2021

UP TO 3X FASTER THAN OUR COMPETITORS

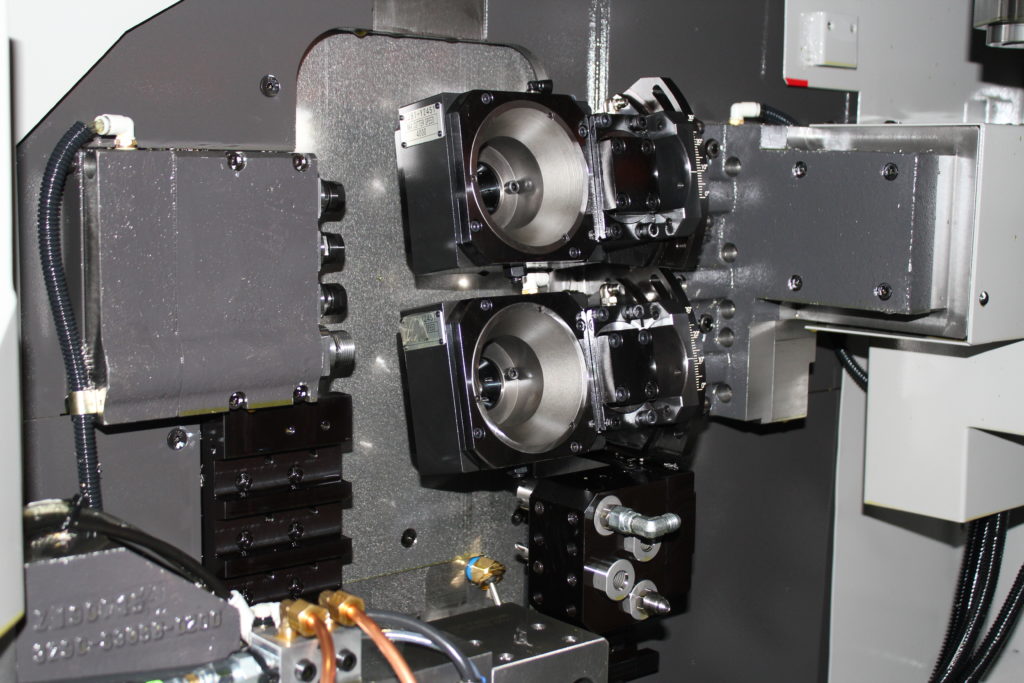

Dual Thread Whirling Units on S206-II

Overview

- Tsugami S206-II is heavier than competitor machines – more weight translates to more mass which can allow for faster metal removal.

- One-piece base casting supports the entire machine tool assuring maximum rigidity.

- The Tsugami Thread Whirling unit is hands down the largest and most robust in the 20mm class of machines.

- The Tsugami S206-II can be mounted with dual thread whirling units to shorten cycle times.

- The front cross tools on the S206-II have 10,000 rpm capability, a key benefit for small drills and end mills.

- All of the machine-driven attachments utilize a tang drive instead of gear drive, thus minimizing gear noise transference to the cutting tools.

- More modular live tool positions are available on rear gang slide allowing more tooling flexibility.

Machine Design

With the Tsugami S206-II machine weight being over 35% more than competitive machines, this robust platform brings you a variety of benefits regarding machine construction. More weight translates to more mass which can allow for more metal removal. The machine also incorporates a complete one-piece base casting supporting the entire machine tool.

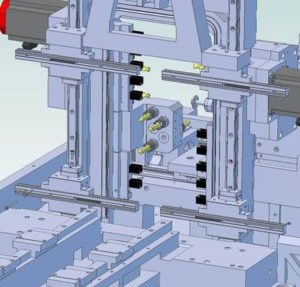

The Tsugami box design for way construction is more rigid for milling and turning. All tools are kept inside the ways during cutting, the ID tools and driven tool overhang is minimized so rigidity is increased as the moment of deflection of the tool overhang is minimized.

Tsugami “In The Box” Design

-

X and Y Linear Rails surround the spindle

-

Box Style X, Y and Y frame design eliminated the possibility of cantilever forces

-

All of the tools are “inside the box” construction of the way system

The S206-II also employs our electronic guide bushing system which has been utilized by Tsugami for many years. This integral motor spindle system provides smooth, beltless, servo motor electronic drive to the guide bushing. The main spindle and guide bushing are electronically linked so rpms match and no parasitic loss is seen by the main spindle as it does not have to drive the guide bushing assembly.

The Tsugami machine’s additional mass and rigidity allow you to push a tool harder and also experience longer tool life. The machine’s design and the ability to also utilize larger bearings in the guide bushing motor is such that higher feeds and speeds are commonplace with no machine-induced chatter or vibration. Because of this robust design, tool spacing is increased, letting chips clear and be removed from the process as well as giving operators more access to the cutting tools themselves.

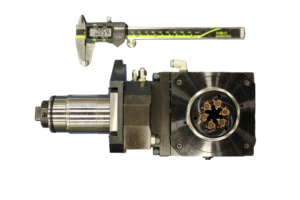

An important aspect of this design by Tsugami is that it keeps the live tool drive short and the design of the units compact, which increases the tool rigidity. These live units are bolted directly to the cast frame. This minimizes tool deflection and allows for better finishes and higher feeds and speeds. The Tsugami whiling unit is compact and rigidly fastened to the machine in comparison to the competition.

Whirling Specific Design

Tsugami Thread Whirling Unit with Size Reference

The Tsugami Thread Whirling unit is hands down the largest and most robust in the 20mm class of machines. Our competitors’ design allows for most of their tools, especially the whiling unit to be cantilevered against the way system. The X axis in particular is above the cutting tools. The drive system for live tools is vertical, thus requiring long shafts which can lose power transmission due to the length. The base of this machine is also very short and has a cantilevered design. The other factor with this design is if you add the B axis option, this tool system is again much further away from the X axis ways and support for these tools is minimal.

Because of the robust design of the Tsugami one-piece base casting, the attached machine frame, and the large guide bushing bearings, the machine can run 20mm stock through the main and sub spindles without bar feed bar prep. The main spindle clamping toggles have been increased from two to three, dramatically improving work holding. The rigidity of Tsugami machines, extends tool life over the competition. This will result in less scrap, downtime, overall part quality and more high-quality parts end of each week.

The front cross tools on the S206-II have 10,000 rpm capability, a key benefit for small drills and end mills. All of the machine-driven attachments utilize a tang drive instead of gear drive, thus minimizing gear noise transference to the cutting tools. More modular live tool positions are now available on rear gang slide which allows for more room.

An often-overlooked benefit of the Tsugami machine is our Standard Cut Off routine or Safe Start routine. No matter where you are in the program, regardless of where the bar is or what tool is active, after a stoppage the machine will run its auto cut-off routine before starting the part program.

The 100% FANUC system is extremely reliable with parts and service throughout North America supporting Rem Sales and our Distribution teams.

Interested in learning more? Connect with our team to see how the Tsugami S206-II and Dual Thread Whirling Units can work for you!